- 30-day returns

- Fast shipping

- Secure payments

- Over 300,000 products

Product Description

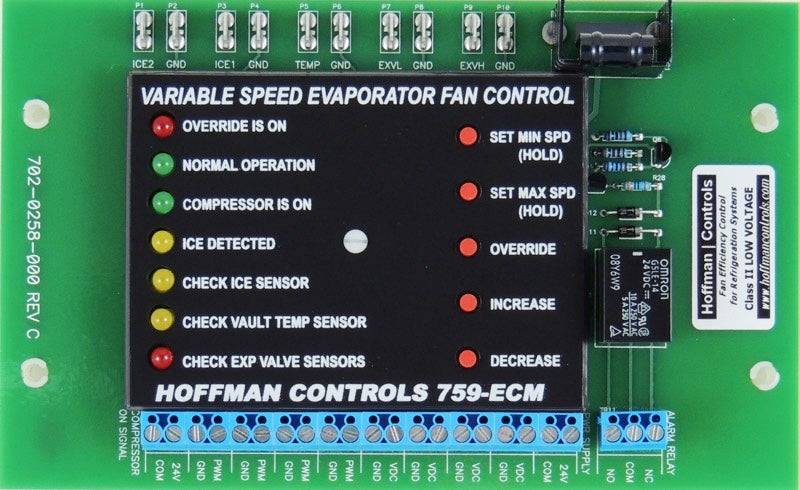

Hoffman Controls - 500-0041-059 The 759-ECM is a true Variable Speed ECM Evaporator Fan Speed Control for walk in and reach in Coolers and Freezers. The 759 Control allows maximum efficiency, reduced compressor run time, reduced product shrinkage, and increased product shelf life by operating the evaporator fan(s) at an OPTIMUM speed at all times. When the refrigeration system shuts off active cooling, the intelligent 759 Control monitors the vault temperature and runs the ECM fan(s) at the minimum required speed. As the refrgerated space slowly increases in temperature, the fan(s) adapt their speed for consistent temperatures in the space, eliminates air temperature stratification and optimizes compressor off time during a cycle. This efficiency is most pronounced after the product has cooled to vault temperature and as the space temperature warms up, the fan(s) can then draw excess cooling from the product to help keep the vault at a lower temperature than would normally be possible. As the temperature increases to the point where the refrigeration system must activate cooling, the fan(s) increase to maximum speed. The 759 Control constantly monitors each refrigeration cycle and OPTIMIZES ECM fan speed for a REMARKABLE 63% ENERGY SAVINGS over constant speed Shaded Pole motors. The installation of the 759 Control does not require changes to the thermostat or compressor connections. The Control uses sensors to monitor the vault, coil and expansion valve temperatures and provides a PWM and/or 0-10Vdc or 10-0Vdc (fail safe) 100mA (12 motors) ECM motor drive signal. Also the Control has an option to directly monitor the compressor/fan ON signal.

Features- Can control single or multiple ECM motors (up to 12) with continuously variable speed using PWM and/or 010Vdc or 10-0Vdc (fail safe) signals.

- Inputs consist of four supplied sensors to monitor vault temperature, expansion valve high low temperatiures and evaporator coil temperature.

- An optional fifth sensor can be used to monitor a second evaporator coil temperature.

- Monitors the refrigeration cycle and continuously adapts without any set-up.

- The installer has the option to set the ECM motor maximum and/or minimum fan speed.

- An Override button is provided to bypass the control functions and keep the fan(s) running at maximum speed.

- Fault detection LED's are provided for coil icing, bad expansion valve sensors, bad vault temperature sensor, and bad icing sensor.

- Also display LED's are provided for normal operation, control override, and compressor ON.

- 24V/10A NO NC switch contacts are provided to activate an external alarm or warning light when an expansion valve sensor fault or override operation is detected.

- If desired there is an optional 24Vac Compressor ON input signal which can be used instead of the expansion valve sensors.

- Optional 759 Enclosure Kit (P/N 520-0121-003), 759 Transformer Kit (P/N 500-0041-059) and 759 VDC ECM Motor Kit (P/N 520-1800-759) or 759 PWM ECM Motor Kit (P/N 510-1800-759) are factory available.