- 30-day returns

- Fast shipping

- Secure payments

- Over 300,000 products

Product Description

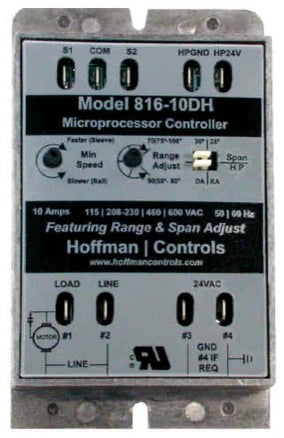

Hoffman Controls - 814-10EH The NEW 814-10EH Microprocessor Electronic Head Pressure Control modulates (varies) condenser fan motor speed in low ambient temperatures, varying the air volume through the condenser to regulate head pressure. This model’s dual sensor input allows for the control of one or two independent refrigerant circuits sharing the same fan motor(s). Only open, drip proof, PSC or Shaded Pole motors are applicable for motor speed regulation. The Controller monitors the liquid line temperature(degrees of excessive sub-cooling) which is directly proportional to the head pressure. Speed modulation begins at 80°F liquid line(65°F˜ ambient temperature) and proportionally reduces the fan to minimum speed once the liquid line temperature reaches 50°F(30°F˜ ambient temperature). Power to the motor is removed at liquid temeperatures equal to or below 50°F. At 53°F the fan restarts at full speed; then modulates to minimum speed. When ambient temperatures are at or below approximately 30ºF(50º liquid temperature), the condenser fan motor will cycle between minimum RPM and “off” to maintain proper condeser temperature (head pressure). The above describes a 30ºF span (80ºF to 50ºF) function; a 25ºF span is also available. The 25ºF span is recommended for High Efficiency systems; 30º span for typical systems. Variable condenser airflow is modulated from full to minimum speed over the selected span. The control's purpose is to assure adequate pressure in low ambients: a) for maintaining adequate pressure differential for the expansion device, b) assure an adequate pressure to eliminate freezing of the DX coil for A/C applications, c) eliminate oil foaming (oil migration) and/or liquid slugging. For Heat Pump installations, the Heat Pump input is used to override condenser fan speed regulation. Heat Pump Mode Direct Acting “DA” and Reverse Acting “RA” jumpers are configured based on the manufacturer’s method of energizing or de-energizing the reversing (changeover) valve. Properly configured, the Heat Pump will override speed regulation and allow full speed condenser fan operation when in the heating mode. The exclusive sensor Range Adjust is provided to optimize the Controller’s performance for specifically, TXV (Thermal Expansion Valves) or Capillary Tube/Orifice systems. The Controller’s 25°F or 30°F span can be adjusted anywhere from 55°F-80°F to 75°-100°F or 50°F–80°F to 70°F–100°F to ensure optimum performance for the specific expansion method. A variable Minimum Speed Adjustment is available to compensate for the bearing type employed by the fan motor. A minimum of 400-RPM for sleeve bearing motors, and 200-RPM for ball bearing motors is recommended. The 814-10EH control includes a transformer within the controller and does not require an external 24VAC power source.

Features- Microprocessor Technology

- One control for every application and refrigerant (2 circuits)

- A special “Range Adjust” allows differentiation between TXV and Capillary Tube/Orifice applications for optimum low ambient performance (Exclusive Feature).

- 25° or 30° (span modulating range) for High or Typical Efficiency units (Exclusive Feature).

- Multi voltage model.(115/208-230/460 VAC) (Exclusive Feature).

- Applicable for all refrigerant types.

- Eliminates the need for system penetration.

- Monitors liquid line temperature (excessive liquid subcooling) for maintaining condensing temperature pressure.

- Single or Dual sensor capable (Exclusive Feature).

- Full voltage start ensures proper fan rotation.

- Cycles fan “OFF” once minimum flow is achieved.

- Eliminates compressor “slugging” (oil migration).

- Simple field installation.

- Replaces inferior fan cycling controls.

- Additional 2nd Sensor Kit — Part Number 100-0017-001.

- Optional Adjustable Sensor Simulator — Part Number 5100027-000

- Automatic minimum speed adjustment procedure by software.

- Optional Weatherproof Kit (NEMA 3R) — Part Number 5450202-007.