- 30-day returns

- Fast shipping

- Secure payments

- Over 300,000 products

Product Description

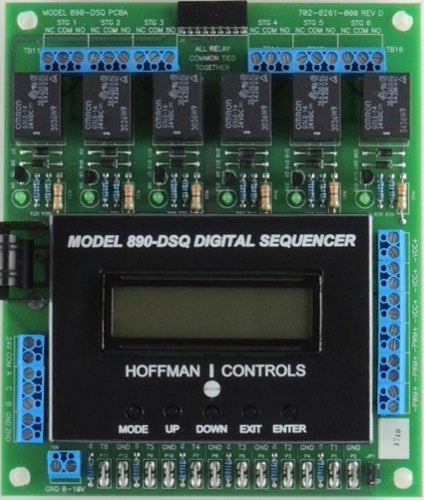

Hoffman Controls - 890-6DSQ The 890-DSQ Series universal sequencer is a microcontroller based step and vernier controller for managing multiple loads (condenser fan motors, heater elements, compressors etc). The sequencer has six resistance or 0-5 VDC inputs which can be used to sense temperature, pressure, voltage, or resistance. There is also an additional 0-10 VDC input for those devices that require a wider voltage range. The number and type of sensors used can be selected. The sequencer's sensor inputs can operate over a 0.0°F to 115.0°F temperature range, a 0 to 1000 PSI range, or the single 0-10 VDC range. The 890-DSQ Series has two types of outputs, fixed relay stages and a variable stage used to modulate EC motors or SCRs. Only the fixed relay stages are activated when a traditional stepped output is required. Both the fixed stages and variable stage are activated when a continuously variable output is desired. The 890-DSQ Series has 6 staged outputs along with a 0-10 VDC, 10-0 VDC and a 17.5 volt, 80 Hz PWM variable stage output. The number of outputs used can be selected. For those applications that require more capability, a plug-in expansion board with 6 additional output stages is available for a total of 12 fixed output stages. The sequencer can be monitored and set either locally, using the 32 character LCD screen and 5 push buttons, or remotely using a Modbus RTU master control. Either operating method allows access to all the sequencer's parameter choices and sensor readings.The 890-DSQ Series is available in a 6 stage model with isolated SPDT relay outputs. The sequencer operates the relays in incremental steps, in sequence, by referencing the input sensor's values. Each stage's turn on and turn off point can be individually selected for the application. The fixed output stage's operation may be monitored by observing the LED indicator as each relay energizes. The operation of the EC motor or SCR output may be monitored by watching the LCD screen's variable stage (VS) value (0 - 100%). The 890-DSQ has a secondary set of programmable set points which can be activated by closing an external contact. The sequencer also has a settable Emergency ON feature. If any of the sensor input values exceed the Emergency ON value, all the sequencer's stages will come on. When all sequencer stages are concurrently called to be on, they will sequence on, one at a time, over a 0.1 to 10 second selectable interval. The amount of control differential (hysteresis) is also selectable. When used with an EC motor or SCR as the variable stage, the 890-DSQ Sequencer becomes a true vernier control. The EC motor or SCR modulates between stage activations and deactivations to provide a continuously variable output. The variable stage's 0-10 VDC, 10-0 VDC and 17.5 volt 80 Hz PWM outputs provide a modulating signal for either EC motors or SCRs. The PWM/VDC output levels can also be scaled to match the selected EC motor's minimum and maximum speed operating specifications. A total of nine (9) EC motors may be driven from either (or both of) the VDC or PWM outputs. A total of 90 mA is available to operate the SCRs. The 0-10 VDC, 10-0 VDC and 17.5 volt 80 Hz PWM signals are derived from either the 0-10 VDC input or the six 0-5 VDC inputs (temperature or pressure). The 890-DSQ Sequencer incorporates a loss of power, auto reset feature. If 24 VAC power is not present for less than 15 milliseconds, then no disconnection occurs. A power loss of 15ms or greater will result in an auto reset of all stages. When power is restored, the appropriate stages will systematically sequence back on line based on the sequencer input signal. This feature eliminates “relay chatter”. The 890-DSQ Sequencer is a direct-acting controller (energizes on a sensor input rise) and is factory calibrated for A/C liquid line sensing.

Features- Lockout Code.

- A/C liquid line temperature sensing using up to 6 sensors.

- A/C line pressure sensing using up to 6 sensors.

- Manual or remote operation.

- Continuous or stepped output capability that can be combined to achieve continuously variable output.

- PSC and/or EC motor operation capability.

- Up to 12 stepped output stages, all with settable hysteresis.

- Emergency ON set point (all stages on).

- Secondary set of set points.

- FIFO, LIFO or Binary Encode staging methods.

- Individually selectable stage turn on and turn off points.

- Large 32 character LCD screen for readout of values and setting parameters using the menu system.

- Low voltage pilot duty isolated relay outputs.

- Multiple input/output functions.

- Adjustable staging.

- Momentary Loss of Power protection.

- Relay stage LED indicators.

- Optional staging intervals.

- Loss of Power Auto Reset.